弊社製品は、「播州織」の特徴である「先染め」です。

長年に亘り、OEMでブランドハンカチを5,000種類以上、多数の日傘用の生地や各種生地を織って培った高い技術力と応用力で、ドビー織物・ジャカード織物を製織しています。

織物の中で最も難しいとされるハンカチで培った高度な織物技術を用いた高付加価値な商品は、世界トップレベルを誇ります。

また、弊社は工場でもあるので、デザイン・設計~製織まで一貫して行え、細かな「紋」の修正、「色合わせ」が可能です。

さらに多品種小ロットにも対応しています。

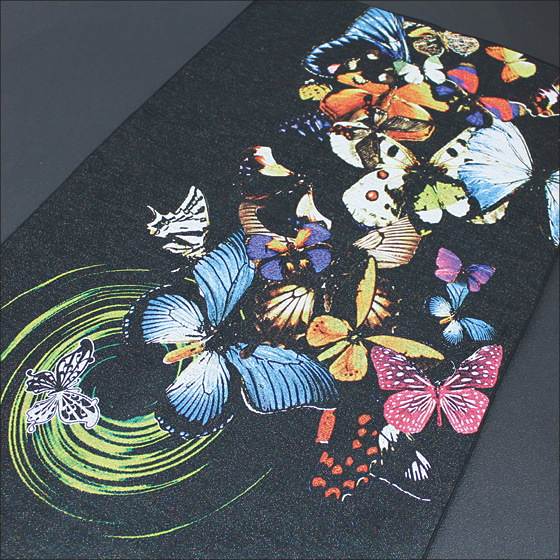

近年、フルカラー写真織を初め、先染め織物を中心に新たな分野を切り開いています。

また、他産地とのコラボも積極的に行い、新しい技術開発にも積極的に取り組んでいます。

写真織製品「蝶のマルチクロス」

自社ブランド Lumiebreで販売中

職人

弊社の工場長は、親子二代で職人をしています。

幼少期から工場に出入りし、父の職人としての背中を見て育った息子が現在は工場長を務めています。

父から息子へと受け継がれた伝統と技術を基に、妥協のない製品作りを心掛けています。

幼少期から工場に出入りし、父の職人としての背中を見て育った息子が現在は工場長を務めています。

父から息子へと受け継がれた伝統と技術を基に、妥協のない製品作りを心掛けています。

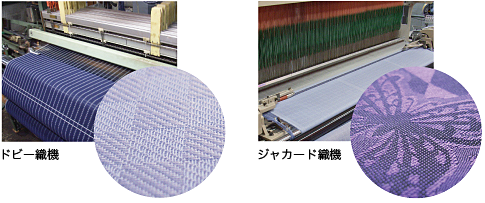

設備

ジャカード織機、ドビー織機の各種織機を揃えていますので様々な製織に対応出来ます。

ドビー織機の中には旧式の力織機も所有しており、現在も稼働しています。

また、産地の機屋(製織工場)とも提携しています。

ドビー織機の中には旧式の力織機も所有しており、現在も稼働しています。

また、産地の機屋(製織工場)とも提携しています。

※ジャカード織機 … 経糸(たていと)を1本1本を独立して動かせるため、複雑な模様も織ることが出来ます。

※ドビー織機 … 経糸(たていと)をグループ単位で動かします。規則的なチェック模様などのリピート柄を織るのに適しています。